Pad printing is a widely used printing technology primarily employed for post-decorating flat surfaces in the promotional products industry. This technique allows for the application of intricate and detailed designs on various shapes and materials, making it popular in numerous other industries as well. With this method, printing can even be done on slightly curved or convex surfaces, although the curvature of the product limits the size of the logo that can be printed. Pad printing enables precise and durable printing of corporate logos and messages. For instance, items like plastic pens, keychains, and water bottles are frequently decorated using this method.

The Pad Printing Process

The pad printing process involves several steps, ultimately transferring ink onto the desired surface:

Initial Step: Aligning the ordered product, the received artwork in the appropriate format, and the customer's vision to create a visual plan. Our graphic designers prepare the visual design so that you can see your company's logo in a technically feasible size. Once you approve, the preparation process begins.

Preparation: The first step is creating the film and printing plate. The film is printed color by color, and the logo is transferred onto the cliché from the film(s) through exposure. The cliché is a metal plate coated with a photosensitive emulsion. During exposure, the emulsion at the logo's location remains soft and can be washed away, while the exposed areas harden. The cliché is thus a metal plate with a recessed area where the ink will be applied.

Ink Application: The ink is applied to the printing plate, and a blade removes the excess ink, leaving it only in the recessed areas.

Using the Pad: The silicone pad picks up the ink from the recessed areas of the printing plate and transfers it onto the product. The advantage of the silicone pad is that the ink easily adheres to it, but once the ink is pressed onto the product, no residue remains on the pad, allowing the next product to be printed. The pad's flexibility enables it to adapt to slightly curved surfaces, allowing fine, detailed graphics to be printed clearly.

Printing Additional Colors: Pad printing machines come in single-color, two-color, or four-color variants. With a four-color pad printing machine, CMYK gradient graphics can also be printed. The color graphic is separated into four basic colors, and raster printing on the product creates the gradient graphic.

Why and Where is Pad Printing Used?

Although pad printing has taken a back seat with the rise of UV printing, it still has numerous advantages that make it widely used across various industries. Some of the benefits compared to other technologies include:

Pantone Color Accuracy: For those who require exact color matching for their branding elements on products or promotional items, pad printing is recommended.

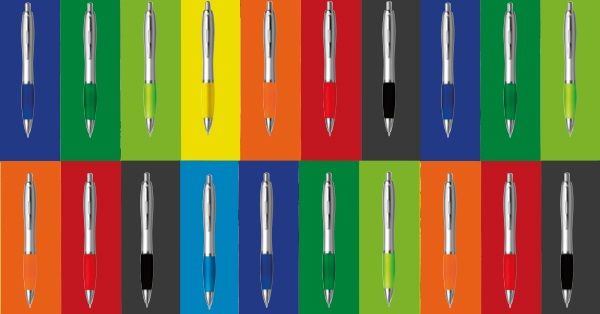

Versatility: Pad printing can be applied to various materials (e.g., plastic, metal, glass, ceramic), making it suitable for printing on automotive parts, electronic devices, and medical instruments. In the promotional products industry, we primarily use it for decorating small items such as ballpoint pens, keychains, USB drives, power banks, tape measures, and notebooks. It also works well on wood, bamboo, and metal products. While the uneven surface of natural materials may affect print quality, we inform customers of this when placng an order and offer alternative products or other branding methods.

Cost-Effectiveness: Pad printing is a relatively inexpensive printing method, especially when printing large quantities of products. The one-time costs - film and cliché preparation - are spread over the large volume, making the per-unit costs acceptable.

Ideal for Small Items: Pad printing allows for extremely intricate and detailed designs to be printed on small items.

Pinpoint Precision: Compared to UV printing, pad printing can produce much sharper and cleaner lines.

Limitations of Pad Printing

After pad printing on metal items, a drying time of 4-5 days is required for the print to become truly durable. Only then can the product be repackaged. If you have an urgent order, choose a product that can be decorated using another method, such as engraving, as it doesn't require drying time or prior cliché preparation.

The maximum print size for pad printing is approximately 8 cm in diameter. Beyond this, the silicone pad required would be so large that the print may become distorted during color transfer.

If you ordered a colored product with vibrant graphics, a white underprint must be applied beneath your logo to achieve color accuracy, which counts as an additional color. While this underprint won't be visible to the naked eye, it may be noticeable upon close inspection of the print's edges. Underprints are unnecessary for gold, silver, or black prints, as these are cover colors.

For products made from natural paper, the material may absorb the ink, resulting in a blurry print.

With particularly large, solid prints, the final result may appear "cloudy."

Contact us, and with our over 30 years of experience, we will handle everything from product design to packaging and shipping. Thanks to our significant stock levels, you'll surely find what you need, whether it's pad-printed water bottles, mechanical pencils, notebooks, folders, kitchen utensils, or any other promotional item to help promote your business. In our facility, we can print, engrave, stitch, iron, and assemble just about anything.

You can read a comprehensive guide on other available branding technologies in this blog post.

Image sources: opening image by Freepik, additional images are our own.